Supply chain planning can often be extremely difficult to manage across enterprise and functional areas within an organization. Functional area expectations, priorities, and preferences can often differ when looking at supply chain planning activities; however, cost effectiveness, process efficiency, and cycle time are common considerations.

This post will look at data for key cost performance measures, such as demand and supply planning costs, total supply chain management cost, and cash-to-cash cycle time. These key cost performance measures quantify how effectively an organization utilizes resources to create value for the customer and how efficiently the supply chain operates. The data presented is taken from APQC’s Open Standards Benchmarking in supply chain planning and will provide you with an understanding of how your organization’s performance compares to APQC’s benchmarks.

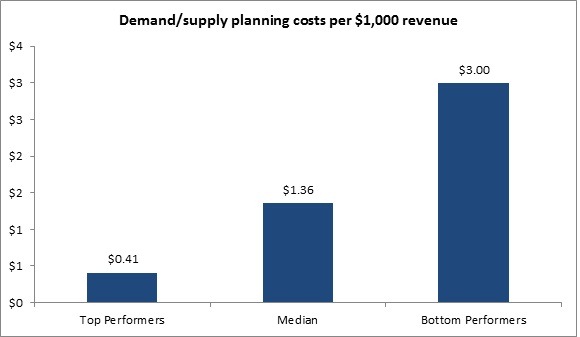

An organization must be conscious of costs when conducting supply chain planning. As shown in the chart below, the median spends $1.36 on demand and supply planning costs per $1,000 in revenue. There is a $2.59 difference per $1,000 in revenue between top and bottom performers. For an organization with $5 billion in revenue annually, this would result in a difference of almost $13 million between the top and bottom performing organizations.

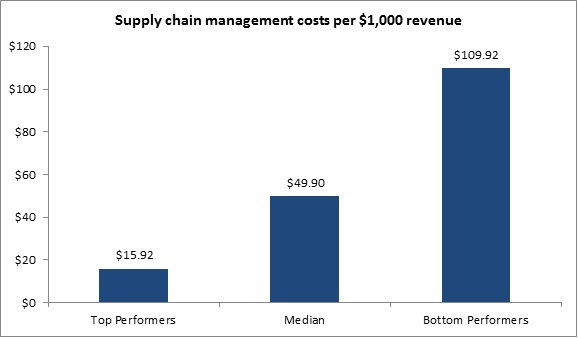

Since supply chain planning can affect an organization’s bottom line, it is important for organizations to examine entire supply chain costs. According to APQC’s data, there is a significant difference between top performers ($15.92) and bottom performers ($109.92) in regards to the total supply chain management costs per $1,000 in revenue. There is a $94.00 difference per $1,000 in revenue between top and bottom performers, which represents $470 million in potential savings for an organization with $5 billion in revenue annually. Demand and supply planning costs per $1,000 revenue differs by $49.09 between top and median performers, which potentially has a $300 million savings. This information may help your organization to strategically plan and set goals that are better aligned with organizational needs.

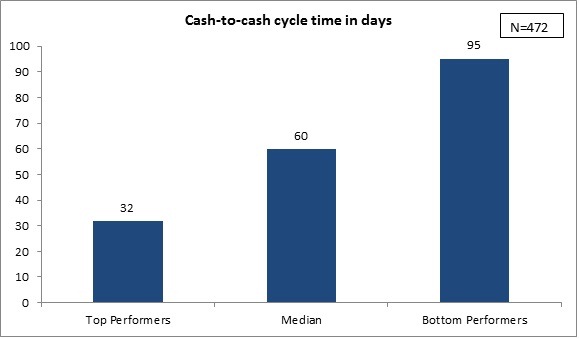

Top performing organizations have significantly lower cash-to-cash cycle times. Top performers have a cash-to-cash cycle of slightly over a month. For median performers, cash-to-cash cycle time is 60 days. Organizations must strive to reduce their cash-to-cash cycle time to free up working capital that can be used to invest in other areas.

What can an organization do to optimize its supply chain? Top-performing organizations have found ways to reduce supply chain planning costs, as well as cash-to-cash cycle time. Organizations can optimize supply chain planning by standardizing policies and processes. Cross-functional alignments in supply chain planning policies are necessary in order to have standardized supply chain planning processes. Standardizing supply chain planning processes across functional areas will help optimize cash-to-cash cycle time by freeing up operating capital. An organization can also free up capital through inventory optimization, streamlining invoice processing, and evaluating inefficient billing processes. Supply chain plans and cash-to-cash cycle times should be monitored regularly to help organizational supply chain planners make changes as the need arises and to be able to do so in a cost-effective manner. Both Standardization and operational visibility help organizations maintain a competitive advantage.

As organizations begin to see how supply chains affect spending and organizational efficiency, more external networking will occur and relationships will be established. Organizations will start to outsource, or increase business with suppliers and providers. This relationship creates a win-win for both the external source and the organization.

How is your organization’s supply chain performing in comparison to other organizations?

Learn more about supply chain management research and metrics by visiting APQC's supply chain management expertise page.