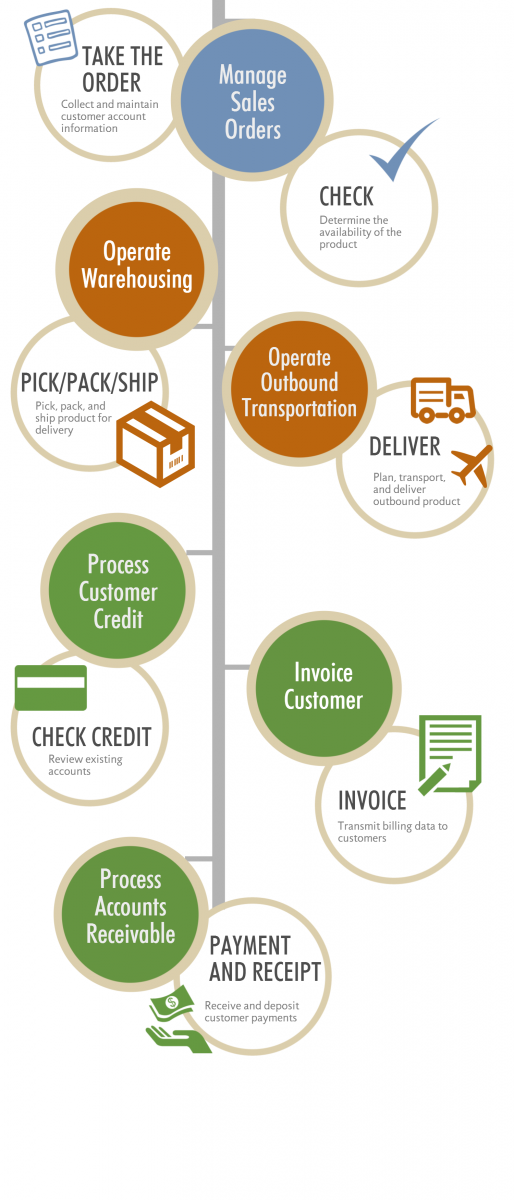

APQC recently published an article entitled End-to-End Mapping of an Order-to-Cash Process. The idea was to illustrate the workflows in each stage of the end-to-end process as well as depict how upstream activities can have an impact—positive or negative—on the ultimate speed at which inventory is converted into cash.

Obviously, a slow pace of order fulfillment will hinder what’s known as the cash conversion cycle (cash buys direct materials that turn into inventory that eventually turns back into cash). Surely, the people on the accounts receivable (AR) team care deeply about the following metric in APQC’s Open Standards Benchmarking database: cycle time in days from transmission of invoice to receipt of payment. A quick look at relative performance via APQC’s Benchmarks on Demand tool shows a startling gap between top and bottom performers. There were 491 organizations that completed this assessment question. The top performers got bills out the door and then received payments from customers in 21 days or less. The bottom performers needed at least 44 days. AR people who want to pick up the pace can easily calculate what it costs not to improve by invoking a tired-and-true concept: time value of money.

But what about process owners in those upstream operating functions—for example, packing and delivering products to customers? If they haven’t done so already, they ought to investigate what it is costing in hard dollars to go slow.